Reduce and eliminate exposure sources

Eliminate processes or tasks involving lead. If elimination is not possible,

substitute lead-free materials in place of lead in these processes or tasks. If substitution is not possible, use a combination of the following:

-

Install

Engineering Controls:

-

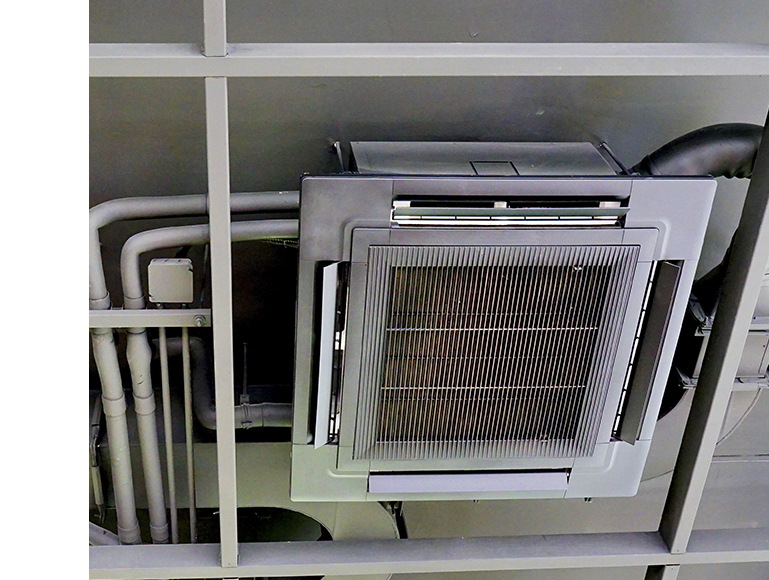

Install and properly use a local exhaust ventilation system for lead operations.

-

Attach power tools to a commercial high efficiency particulate air (HEPA) vacuum. Consider using a shroud for better dust collection.

-

Enforce

good housekeeping practices:

-

Always use safe cleaning methods (e.g., wet mopping or vacuuming with a toxic dust HEPA vacuum). Never clean work areas by dry sweeping or blowing with compressed air.

-

Ensure workers practice

good hygiene:

-

Provide appropriate PPE for the assigned task(s) at no cost to workers and ensure that it is used. This can include respirators, coveralls, hats or head coverings, gloves, vented goggles, shoes or disposable shoe covers, and other items, as needed.

- Using respirators requires developing a

respiratory protection program, which includes the following:

- Ensuring that workers are medically fit to wear a respirator.

- Selecting the correct type of respirator and filter.

- Fit testing workers to ensure proper face sealing and protection.

- Training workers on the use, care, and storage of respirators.

For more information on respiratory protection program requirements, see

Cal/OSHA’s fact sheet on respiratory protection (PDF).

Review the Cal/OSHA Occupational Lead Standards for more information about reducing and eliminating exposure to lead. See Standards, Methods of Compliance, Sections (e)–(i).

Learn more: