Case Report: 11CA004

Roofing supervisor dies when he falls through skylight

Download a PDF to print this report:

Roofing supervisor dies when he falls through skylight (11CA004, PDF)

Summary

A roofing supervisor died when he fell through a skylight while moving a vacuum hose. The victim was supervising the vacuuming of roof rock off a flat roof when he picked up the hose to move it out of the way of the vacuum operator. As the victim was moving the hose, he fell through the skylight. The key factor that contributed to the victim's death was working in close proximity to an unguarded skylight. The CA/FACE investigator determined that in order to prevent workers from falling through skylights, roofing companies should ensure that:

- Fall protection measures such as skylight screens or covers, guardrails, or a personal fall protection system are used for employees working within 6 feet of a skylight.

Introduction

On Tuesday, April 21, 2011, at 2:45 p.m., a 45-year-old Hispanic roofing supervisor died when he fell approximately 30 feet through a skylight. The CA/FACE investigator received notification of this incident on April 22, 2011, from the Monrovia District Office of the Division of Occupational Safety and Health (Cal/OSHA). On May 5, 2011, the CA/FACE investigator interviewed the employer's safety specialist and obtained photographs of the incident scene. Copies of the police and coroner reports were obtained. Telephone interviews were conducted with two co-workers of the victim.

Employer

The employer of the victim was a construction company engaged in roofing, waterproofing, and construction management. The employer was licensed in California, Nevada, and Arizona. The company had been in business since 1945 and had over 120 employees.

Written Safety Programs and Training

The company had a written safety program and Injury and Illness Prevention Program (IIPP). As part of their safety program, the company held two documented safety meetings every month that covered categories pertinent to the construction and roofing industry. The fall protection training covered safety practices while working around skylights, including personal fall protection, guardrails, and skylight screens or covers.

The company had an on-the-job training program that provided documented monthly safety training to employees in both English and Spanish. The victim had received training and often conducted the training of other employees on roof safety.

Worker Information

The victim had worked for the company for 25 years. He was considered a journeyman roofer and was a member of the local union. The victim was familiar with and had experience working on flat roofs with skylights. He was born in Mexico and had been in the United States for 35 years. He had a high school education and spoke both English and Spanish.

Incident Scene

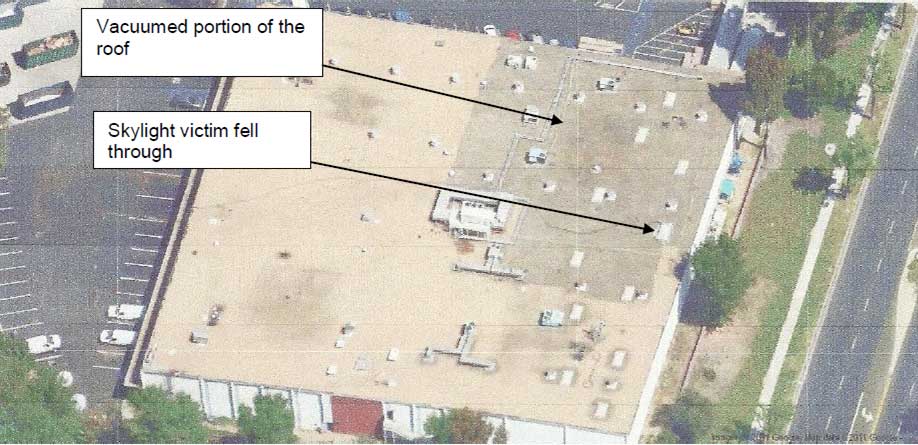

The location of the incident was a large industrial flat roof of a warehouse that measured approximately 150 feet long and 150 feet wide (Exhibit 1). The roof housed many air conditioning units, skylights, vents, and other plumbing and electrical fixtures.

Work Process

This was the second day on the job for this crew. The job was to perform major repairs to the warehouse roof. The first stage was to remove the crushed rock used to cover the roof. This was accomplished by using a truck-mounted industrial vacuum with a six-inch diameter flexible hose used especially for rock and gravel removal from roofs. The truck was parked next to the building and the vacuum hose was stretched from the truck to the roof. The job was a three-person task with one worker operating the vacuum nozzle, a second worker guiding the hose behind the nozzle operator, and the third worker performing various ancillary tasks.

Investigation

The day before the incident, the victim held a tailgate safety meeting describing the job, duties of the crew, and worker safety. The workers were instructed in skylight safety and fall protection. Instead of an approved warning line, caution tape was placed around a portion of the perimeter of the roof to warn workers of the edge. The work began by using the vacuum with a six-inch diameter flexible hose used especially for rock and gravel removal from roofs. Sometime after 1 p.m., one of the workers (worker #1) moved out of the vacuuming area into another more distant area of the worksite, out of visual and audible contact with the victim and the other worker (worker #2). Worker #2 was operating the vacuum nozzle and the victim was guiding the hose behind him. At this time, the victim probably noticed that the vacuum hose was accumulating behind worker #2 and decided to move it out of the way. When the victim picked up the active vacuum hose, he may have been walking backwards and tripped on the base of the skylight, or lost his balance. He then fell through the skylight to the floor 30 feet below. Worker #2 heard an unusual noise and saw the vacuum hose protruding from the broken skylight. He saw the victim on the floor below and notified worker #1. The paramedics and fire department were called and transported the victim to the local hospital where he died from his injuries.

Cause of Death

The cause of death according to the death certificate was multiple blunt force injuries.

Contributing Factors

Occupational injuries and fatalities are often the result of one or more contributing factors or key events in a larger sequence of events that ultimately result in an injury or fatality. The CA/FACE investigation team identified the following as a contributing factor in this incident:

- The victim was working within six feet of an unguarded skylight.

Recommendations

In order to prevent employees from falling through skylights, roofing companies should ensure that:

Recommendation #1: Fall protection measures such as skylight screens or covers, guardrails, or a personal fall protection system are used for employees working within 6 feet of a skylight.

Discussion: In this incident, the victim was trying to prevent worker #2 from tripping and falling, by moving the vacuum hose out of his way. When he moved the vacuum hose he either tripped or lost his balance and fell through the skylight. Most skylights should be considered a "roof opening" and a risk for serious injury and death if workers should trip, fall, and break through. Therefore, in order to prevent falls through skylights, employers should implement and maintain a fall protection program that includes any one of the following:

- Skylight screens or covers capable of withstanding the impact of a worker plus the weight of his/her equipment.

- Guardrails around the skylight with a top and midrail and a vertical height within the range of 42 inches to 45 inches from the upper surface of the top rail to the floor. The rails should be able to withstand a live load of 20 pounds per linear foot applied either horizontally or vertically downward at the top rail.

- A personal fall protection system consisting of a body harness, lanyard, connectors, and anchor points.

Exhibits

Exhibit 1. The warehouse rooftop where the incident occurred showing vacuumed portion of roof.

Exhibit 2. The work area on the roof.

Exhibit 3. The skylight the victim fell through.

Exhibit 4. The incident scene.

Exhibit 5. The base of the skylight.

Exhibit 6. The vacuum nozzle.

References

General Industry Safety Orders Article 2. Standard Specifications. §3209. Standard Guardrails. §3212. Floor Openings, Floor Holes and Roofs. (b) (e)

Construction Safety Orders Article 24. Fall Protection. §1632. Floor, Roof, and Wall Openings to Be Guarded. §1670. Personal Fall Arrest Systems, Personal Fall Restraint Systems and Positioning Devices.

Skylight Fall Protection Awareness and Guidelines - American Architectural Manufacturers Association website

New Test Method for Human Impact on Commercial Skylights - ASTM International website

Preventing Falls of Workers through Skylights and Roof and Floor Openings - National Institute for Occupational Safety and Health (NIOSH) topic page

Preventing Worker Deaths and Injuries from Falls Through Skylights and Roof Openings - NIOSH topic page

Video of Workers Vacuuming Rock from a Rooftop - YouTube

Authors

Hank Cierpich, FACE Investigator

Robert Harrison, MD, MPH, FACE Project Officer

Laura Styles, MPH, Research Scientist

May 18, 2012

Revised November 28, 2012